To Ensure That the Sanitizing Solution for a Food Prep

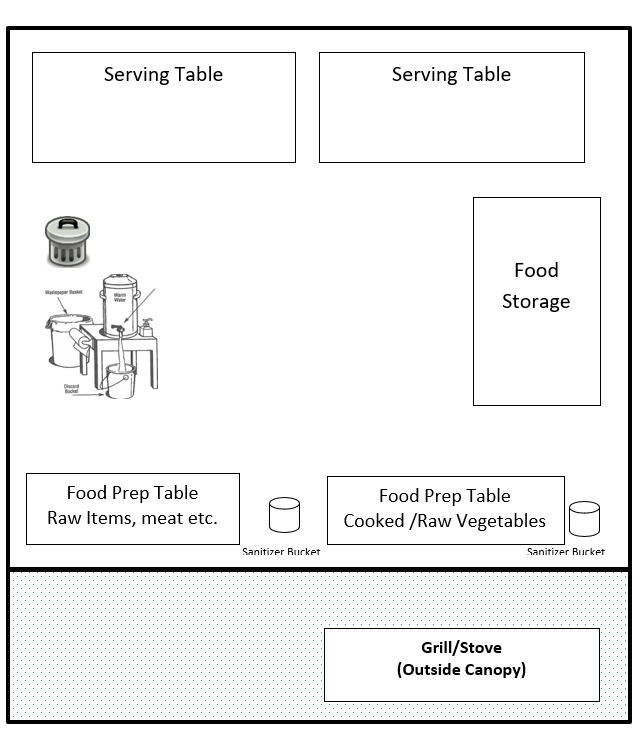

Use this time to implement a clean break if your location requires food prep to be documented in lots and time shifts. There are advantages and disadvantages to.

Restaurant Update Bad Sushi Unlicensed Eateries And Excessive Cockroaches Iowa Capital Dispatch

The water temperature in the wash sink of a three-compartment sink must be at least.

. The hypochlorous solution is represented as Free Available Chlorine FAC that has 80-200 times the sanitizing power of chlorine bleach. CLEANING AND SANITIZING NON-FOOD CONTACT SURFACES Non-food contact surfaces include counters tables appliances and other areas within the footprint of the food preparationstorage areas. The Code does not specify which procedures must be used to ensure the premises and equipment are kept in a clean and sanitary condition.

This is a 4 step process that removes food waste dirt grease and destroys food-borne disease pathogens. Knives and cutting boards in the prep area that are continuous contact with potentially hazardous TCS food must be cleaned and sanitized at least every. Storing a bucket of sanitizing solution on a food preparation surface poses a potential for contamination.

Wash the equipment with hot soapy water. Allow the dishes and utensils to air-dry. The bacteria is in the raw egg mixture.

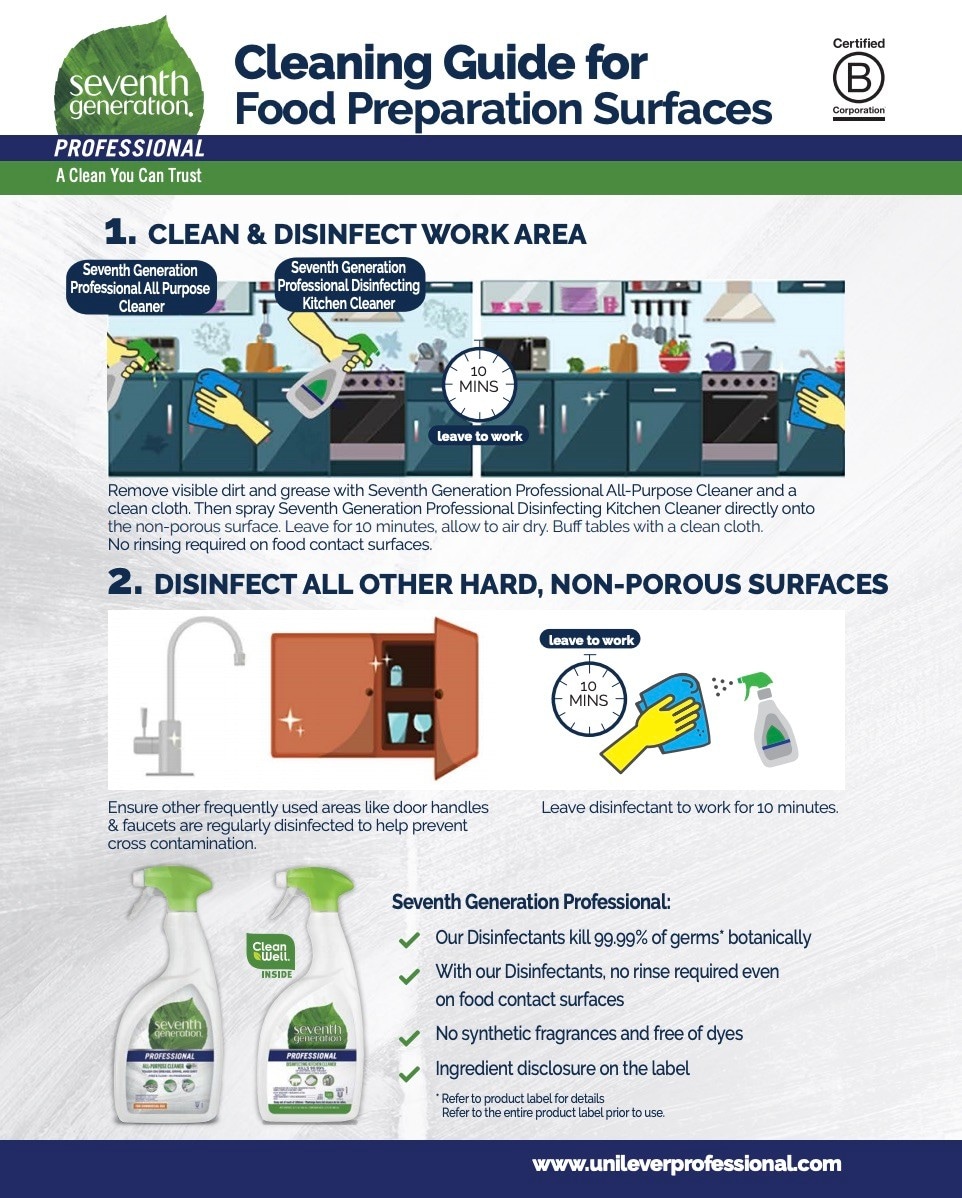

Youll then want to apply a food-grade non-abrasive cleaning solution with a microfiber wipe. Sanitize the surface with food-safe sanitizer. Sanitizers are applied to cleaned surfaces to insure that the surface is free of pathogenic microbes.

ServSafe Practice Test on Cleaning and Sanitizing Chapter 10 based on ServSafe 7th Edition study guide. Simply water deemed safe for drinking and food preparation. Then add in the final step of spraying the sink with a sanitizing solution and let dry.

Rinse the sanitizer if needed per the chemicals directions. This is also one of the most effective food-safe sanitizers in removing biofilms. Surfaces to sanitize.

Quaternary ammonia solution at 200 400 ppm for 30 seconds. All items that come into contact with food must be effectively cleaned and sanitised. This will stop any bacteria from the eggs growing in.

Allow the surface to air dry for a minimum of 30 seconds to a minute to allow the sanitizer to work. Sanitizers should be used on all prep and cooking surfaces on cooking utensils kitchen walls and floors and on all equipment such as grills hoods sinks faucets ovens coffee machines and more. To ensure that the sanitizing solution for a food prep surface will work correctly a food handler should.

It will be help full for both the ServSafe Food Protection Manager test and ServSafe Food Handler Test certificate course preparation. PAA is an effective sanitizer that is active against many bacteria fungi and spores. How often should you change sanitizer water.

Wipe down all surfaces with a second clean cloth immersed in sanitizing solution 100 ppm chlorine or 28 mL bleach per 45 L water. Clean the dishes and utensils in the first sink with soap and warm water. Food-grade sometimes referred to as food-safe sanitizers have been tested and certified safe for food contact.

1 tablespoon of bleach per 1 gallon of water will give you a 50-200 ppm sanitizing solution. The following are the three types of sanitizer solutions that the Minnesota Food Code approves of for use in food preparation outlets. Sanitizers that have not been approved for food contact should not be used in food prep or food contact areas.

Unlike other sanitizers PAA sanitizers function well under cold conditions. Pre-clean the surface with soap and water. Allow to air dry prior to replacing food on shelves.

Lean before you sanitize. This means that even if the sanitizer comes into contact with food it will not be harmful when ingested. SANITIZING FOOD CONTACT SURFACES A solution of bleach and water should be used to sanitize all food preparation and contact surfaces.

Scrape away leftover food on the dishes and utensils. Its important to make sure the sanitizer is strong enough and that you use the sanitizer for the proper amount of time. Our Electrolytes are also food-based additives that have been classified as GRAS Generally Regarded As Safe by the US.

Rinse the dishes and utensils in the second sink with clear clean water. Bleach or Chlorine solution at 50 ppm for 10 seconds. Glass and Dishware.

Kitchen preparation tables cutting boards utensils condiment containers typically left on. The sanitizing step is a mandated part of most state and federal food safety protocols for food contact surfaces. This can be used to sanitize dishes utensils food preparation counters and tables.

It is recommended that food contact surfaces be sanitized with an appropriate bleach solution made by diluting 1 tablespoon of regular bleach approximately 6 strength and with an EPA registration number to 1 gallon of water. Minimum water temperature of the final sanitizing rinse in a high. Rinse the equipment to remove cleaning chemicals and any extra food waste that may have been missed when wiping and washing.

Use a test kit to check its concentration. Wash down all surfaces with a clean cloth immersed in clean warm water and detergent. Clean surfaces using a soap and water mixture or an approved kitchen cleaning solution.

The employees would be. This means you get all the sanitizing power of bleach without the hazards. Apply sanitizer following the manufacturers instructions.

Sanitize the dishes and utensils in a chemical solution or very hot water at least 171F in the third sink. Prepare a sanitizer solution in a bucket or spray bottle. Clean the Food Contact Surface To begin cleaning wipe the surface clean of any visible debris.

There are two types of PAA. Some restaurants may opt for bleach cleaning solutions though bleach can be harmful if. That is OK just be sure you wash the bowl utensil and sink with warm soapy water.

It would be acceptable to store the sanitizing bucket on a shelf below the food preparation surface or on another nearby surface. Careful handling of the solutions must be provided to ensure that none of the solution is spilled directly onto the food. Iodine solution at 124 25 ppm for 30 seconds.

LEANING Removes soiled surfaces to allow effective sanitizing or disinfecting. Acetic aid and hydrogen peroxide. Disinfection is not approved for food contact surfaces.

Top 10 Food Hygiene Courses Edapp Microlearning Programs

/__opt__aboutcom__coeus__resources__content_migration__serious_eats__seriouseats.com__2020__03__20200320-covid-food-prep-gloves-shutterstock-3d4aa015da574e1b937fa5c14b040e1e.jpg)

Food Safety And Coronavirus A Comprehensive Guide

Food Safety Part 1 Hygiene Sanitation Virtual Lab School

Sanitizing Smarter Build Trust And Reinforce Safety With Efficient Cleaning Processes And Solutions

Free Front And Back Of House Restaurant Cleaning Checklist

Food Preparation Cleaners Sanitizing Food Preparation Areas

Everything You Need To Know About Restaurant Sanitation San J

How Sanitizing Protects Your Food Safety

How Sanitizing Protects Your Food Safety

Going With The Food Safety Flow

Food Safety Paho Who Pan American Health Organization

Cleaning Sanitizing Disinfecting What S The Difference

Ensure Food Safety With Sanitizer Test Strips

Everything You Need To Know About Restaurant Sanitation San J

Off Premises Dining Safety In The Restaurant And Foodservice Business Food Safety

Food Grade Sanitizer What Are Approved Sanitizers For Food Service

Comments

Post a Comment